The following are key benefits of our inspection tools:

- Accurate, robust and reliable

- Fast, accurate data analysis and reporting

- High sensor density and sampling rate ensure accurate feature classification and sizing

- Tool designs ensure ease of operation and flexibility

- High magnetic levels ensure accurate feature classification, accuracy and sensitivity.

With over 25,000 kilometers of inspected pipelines, our experts are fully equipped to undertake a wide range of inspection services. Our technical partnership with the ROSEN Group, world leaders in Pipeline Integrity Assessment has ensured that we provide quality innovative and reliable inspection technologies.

BMB Tool

The DSV/ROSEN’s BMB tools are designed to inspect the geometry of pipelines, to locate third-party damage, construction anomalies and to confirm free passage of any other ILI tool. The DSV/ROSEN Geometry tools identify measure and locate any possible obstruction in the pipe.

XGP Tool

The DSV/ROSEN’s XGP tool is a high-resolution geometry and dent sizing tool and is designed to locate buckles, ovalities, stress-induced geometric features and pipeline bending.

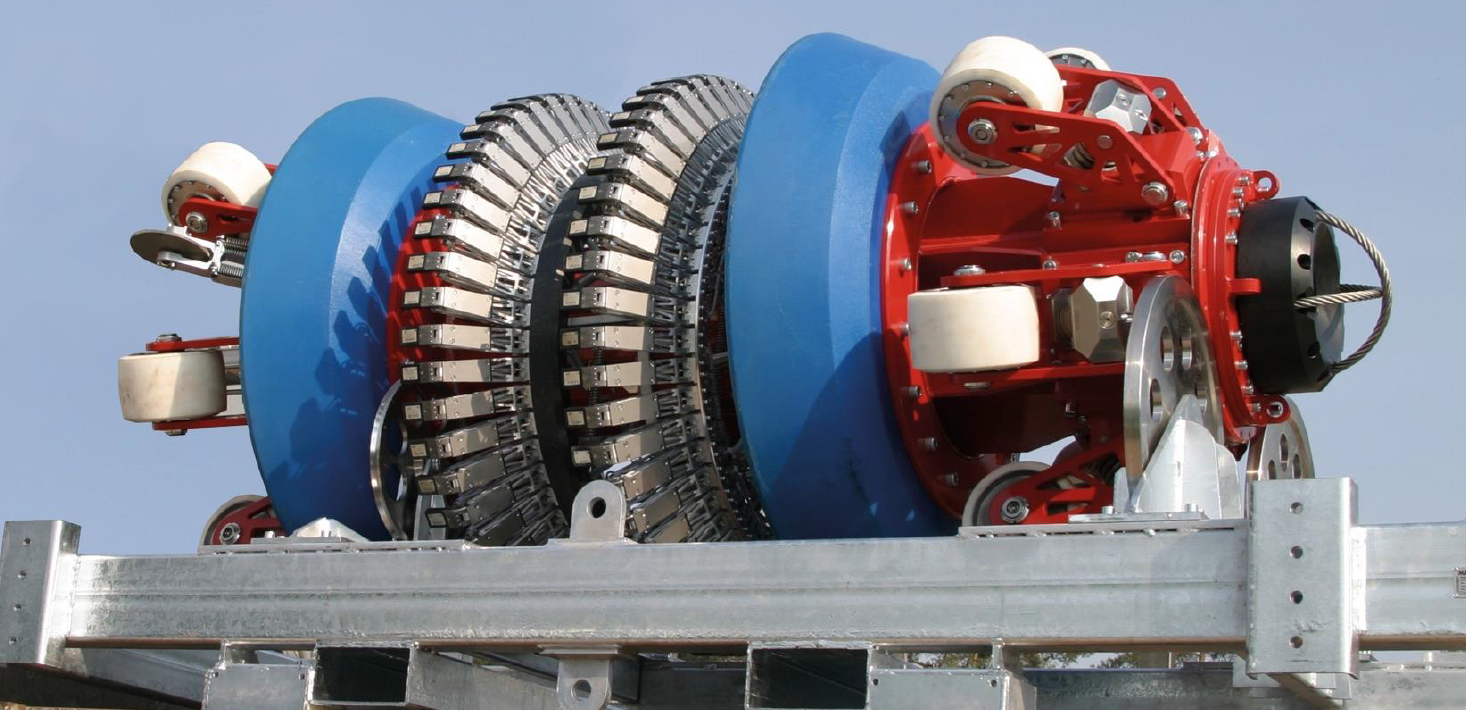

RoCorr MFL-A Tool

DSV/ROSEN’s high-resolution magnetic flux leakage (MFL) inspection tool RoCorr MFL-A is predestined for the detection and sizing of metal loss, girth weld cracks, mill defects and others elongated in circumferential direction.

RoCorr MFL-C Tool

DSV/ROSEN’s high-resolution magnetic flux leakage (MFL) inspection tool RoCorr MFL-C is predestined for the detection and sizing of metal loss, girth weld cracks, mill defects and others elongated in axial direction.

RoCorr UT

Our RoCorr UT service is well suited to address the broad range of metal loss anomalies present in liquid pipelines and helps maintain their structural integrity. It allows direct and highly accurate measurements of pipeline wall thickness. All aspects from the inspection request to the final report are covered with the flexibility to choose from various service options.

Crack and Coating Detection

Pipeline deterioration by stress corrosion cracking (SCC) continues to be an increasing

challenge for the pipeline industry. That’s why DSV/ROSEN targeted this problem as a priority in developing its new high resolution In-Line Inspection tool.

DSV/ROSEN’s challenging pipeline diagnostics team provides customized solutions for pipelines that cannot be inspected with conventional ILI tools. Typical challenges involve access (e.g. no pig traps installed), operating conditions (e.g. flow, pressure, temperature) as well as pipeline geometry (e.g. diameter variations, complex bend geometries etc.).

The unique combination of the specific factors that make a given pipeline and inspection challenge requires a wide range of solutions in order to address each of them. To maintain flexibility and ensure fastest turnaround time, DSV/ROSEN utilizes a tool box approach rather than generic developments with limited application range. By combining these elements ROSEN’s experts tailor the most suitable solution for the individual required.

At DSV/ROSEN, you will find the advantages of having highly specialized units, all under the same roof; whether you require a Fitness for Purpose Assessment or a large-scale integrity program implantation.

DSV/ROSEN can offer you the full range of required systems and services; from high level procedural and organizational definitions to detailed engineering assessments. As part of the DSV/ROSEN group, we are backed up by a substantial R & D team and therefore have access to the most sophisticated technologies – ensuring that you lead the way. Our locally established hubs house their own experts and have direct immediate access to worldwide network of in-house engineers that benefit from our expertise